What Is Carbon Steel Plate?

Carbon steel is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. It also contains a small amount of silicon, manganese, sulfur, and phosphorus. Generally, the higher the carbon content, the greater the hardness and the higher the strength, but the lower the plasticity. According to the carbon content, carbon steel plate can be divided into low carbon steel (C ≤ 0.25%), medium carbon steel (C 0.25%-0.6%) and high carbon steel plate (C>0.6%).

he weight can be calculated by the following formula: Weight = 7.85 * length (m) * width (m) * thickness (mm)

For example, if the MS plate is 3 m in length, 1.5 m in width, and 20 mm in thickness, the weight will be 760.5 kg.

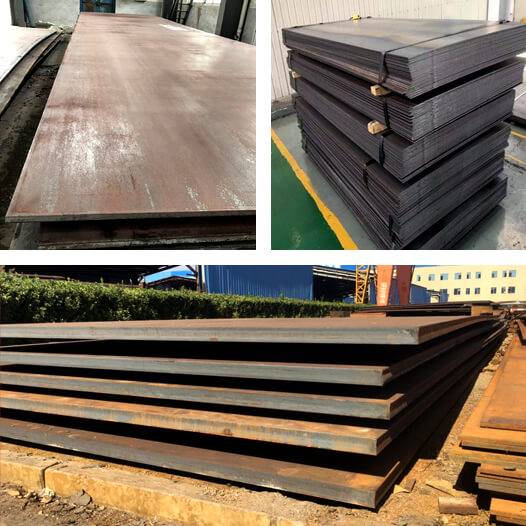

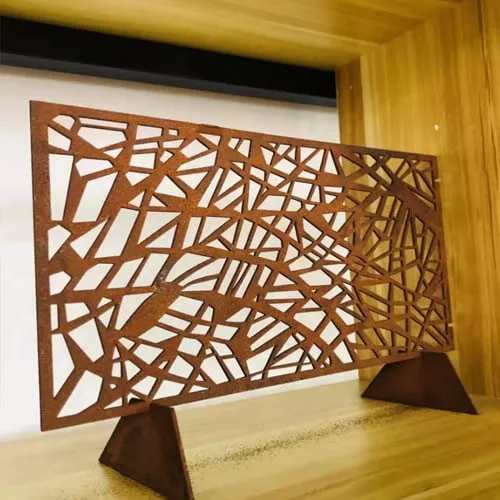

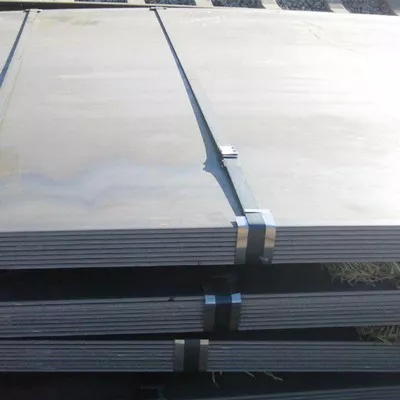

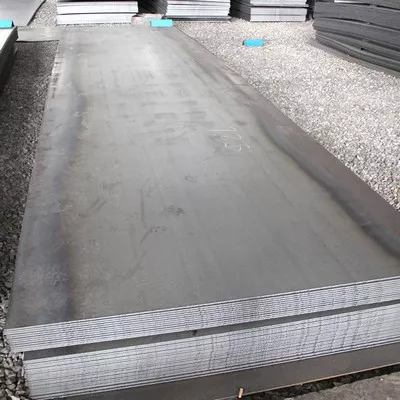

Carbon steel production line

KUAIMA steel company has more than ten years of experience in diversified operations and multi-product transactions, involving round bar, ship plate, seamless pipe, plate, coil, wire, bright bar, pipe fittings and a wide range of carbon steel, alloy steel And more product sizes of stainless steel materials, these products we produce meet national and international quality standards, such as ASTM, ASME, DIN, JIS, ISO, etc. The company has 25 production lines for various products, with an annual output of 500,000 tons, and is committed to Provide high-quality steel products and provide supporting services and solutions for global customers. Welcome to KUAIMA steel company.

Different Types of Carbon Steel Plates

Generally, carbon steel sheet plates are available in different types depending on the carbon content, making method, thickness, and usage.

Carbon Content

There are generally low, medium, high, and extra-high carbon steel plates according to the carbon content.

Low carbon: C content from 0.06% to 0.25%. It is also called a mild carbon plate.

Medium carbon: C content from 0.25% to 0.6%.

High carbon: C content from 0.6% to 0.95%.

Extra-high carbon: C content from 0.96% to 2.1%.

It should notice that as the content of carbon increases, the steel hardness increases, but the final plasticity reduces.

According to the thickness, it can be grouped into thin, medium, thick, and extra-thick carbon plates.

Carbon steel Category

Carbon structural steel

Features: Low price, excellent process properties (e.g. weldability and cold formability).

Applications: General engineering structures and general mechanical parts. For example, Q235 can be used to make bolts, nuts, pins, hooks and less important mechanical parts as well as rebar, sections and bars in building structures.

High quality carbon structural steel

Application: Non-alloy steel for making important mechanical parts, generally used after heat treatment.

Carbon tool steel

Characteristics: Eutectic and over-eutectic steel, high strength, high hardness, good wear resistance suitable for the manufacture of a variety of low-speed cutting tools.

Cast steel

Performance: Casting performance is worse than cast iron, but mechanical properties than cast iron.

Applications: mainly used for the manufacture of complex shapes, high mechanical properties required, and in the process is difficult to forging and pressing and other methods of forming the more important mechanical parts, such as automobile transmission housing, rolling stock hooks and couplings.

We supply and export Carbon Steel in following countries

Malaysia, United Arab Emirates, Indonesia, Saudi Arabia, Iran, Qatar, India, China, United Kingdom, Singapore, Canada, Thailand, Korea, Turkey, Philippines, Egypt, Germany, Italy, Japan, Russia, Vietnam, Australia, South Africa , Portugal, Morocco, Costa Rica, Kazakhstan, Netherlands, Mexico, Brazil, France, Spain, Nigeria, Bangladesh, Kuwait, Iraq, Ukraine, Poland, Jordan, Romania, Oman, Hong Kong, Venezuela, Colombia, Norway, Chile, Te Trinidad and Tobago, Greece, Czech Republic, Belgium, Sri Lanka, Cyprus, Angola, Myanmar (Burma), United Kingdom, Canada, Korea, Thailand, Netherlands, Spain, Turkey, Australia, Mexico, Pakistan, Vietnam, Brazil, Philippines, France, Taiwan, Poland, South Africa, Russia, Nigeria, Kuwait, Czech Republic, Norway, Romania, Egypt, Oman, Sweden, Belgium, Hong Kong, Israel, Colombia, Switzerland, Denmark, Finland, Argentina, Venezuela, Peru, Ukraine , Chile, Bangladesh, Portugal, Ireland, Austria, Algeria, Greece, Iraq, New Zealand, Slovakia, Hungary, Kazakhstan, Slovenia, Lithuania, Serbia, Sri Lanka, Bahrain, Bulgaria, Morocco, Tunisia, Croatia, Jordan, Ecuador, Te Trinidad and Tobago, Estonia, Azerbaijan, Ghana, Lebanon, Cyprus, Dominican Republic, Latvia, Libya, Costa Rica, Cambodia, Macedonia (FYROM), Belarus, Jamaica, Palestine, Turkmenistan Belarus, Jamaica, Palestine, Turkmenistan Belarus, Jamaica, Palestine, Turkmenistan and other countries

Steel Plate

Steel Plate steel pipe

steel pipe Stainless steel

Stainless steel

English

English Spanish

Spanish Russian

Russian Portuguese

Portuguese Section steel

Section steel carbon steel plate

carbon steel plate Steel plate processing

Steel plate processing steel coil

steel coil steel rod

steel rod

Home

Home