317 stainless steel plate

Alloy 317L (UNS S31703) is a molybdenum-bearing austenitic stainless steel with greatly increased resistance to chemical attack as compared to the conventional chromium-nickel austenitic stainless steels such as Alloy 304. In addition, Alloy 317L offers higher creep, stress-to-rupture, and tensile strength at elevated temperatures than conventional stainless steels. It is a low carbon or "L" grade which provides resistance to sensitization during welding and other thermal processes.

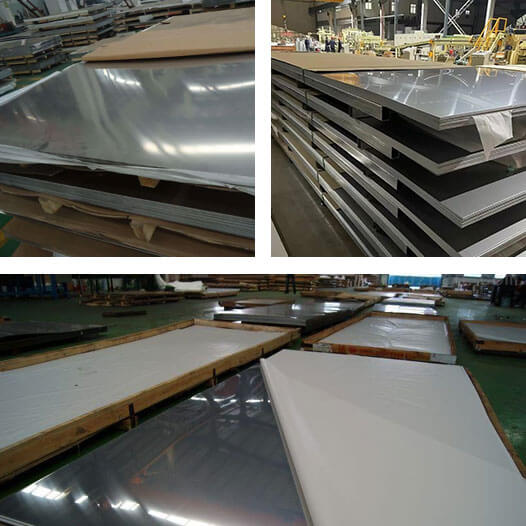

317 stainless steel plate production line

KUAIMA steel company has more than ten years of experience in diversified operations and multi-product transactions, involving round bar, ship plate, seamless pipe, plate, coil, wire, bright bar, pipe fittings and a wide range of carbon steel, alloy steel And more product sizes of stainless steel materials, these products we produce meet national and international quality standards, such as ASTM, ASME, DIN, JIS, ISO, etc. The company has 25 production lines for various products, with an annual output of 500,000 tons, and is committed to Provide high-quality steel products and provide supporting services and solutions for global customers. Welcome to KUAIMA steel company.

Corrosion Resistance of 317 stainless steel plate

The higher molybdenum content of Alloy 317L assures superior general and localized corrosion resistance in most media when compared with 304/304L and 316/316L stainless steels. Environments that don't attack 304/304L stainless steel will normally not corrode 317L. One exception, however, are strongly oxidizing acids such as nitric acid. Alloys that contain molybdenum generally do not perform as well in these environments.

Alloy 317L has excellent corrosion resistance to a wide range of chemicals. It resists attack in sulfuric acid, acidic chlorine and phosphoric acid. It is used in handling hot organic and fatty acids often present in food and pharmaceutical processing applications.

The corrosion resistance of 317 and 317L should be the same in any given environment. The one exception is where the alloy will be exposed to temperatures in the chromium carbide precipitation range of 800 – 1500°F (427 – 816°C). Because of its low carbon content, 317L is the preferred material in this service to guard against intergranular corrosion.

In general, austenitic stainless steels are subject to chloride stress corrosion cracking in halide service. Although 317L is somewhat more resistant to stress corrosion cracking than 304/304L stainless steels, because of its higher molybdenum content, it is still susceptible.

The higher chromium, molybdenum and nitrogen content of 317L enhance its ability to resist pitting and crevice corrosion in the presence of chlorides and other halides. The Pitting Resistance Equivalent including Nitrogen number (PREN) is a relative measure of pitting resistance. The following chart offers a comparison Alloy 317L and other austenitic stainless steels.

Mechanical Properties of 317 stainless steel plate

Values at 68°F (20°C) (minimum values, unless specified)

Yield Strength

0.2% Offset | Ultimate Tensile

Strength | Elongation

in 2 in. | Hardness |

|---|

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

|---|

| 30,000 | 205 | 75,000 | 515 | 40 | 95 Rockwell B |

Fabrication Data

Alloy 317L can be easily welded and processed by standard shop fabrication practices.

Cold Forming

The alloy is quite ductile and forms easily. The addition of molybdenum and nitrogen implies more powerful processing equipment may be necessary when compared with the standard 304/304L grades.

Hot Forming

Working temperatures of 1652 – 2102°F (900 – 1150°C) are recommended for hot working processes. Do not work this alloy below 1742°F (950°C). If the final forming temperature falls below this threshold, a solution anneal of 1976 – 2156°F (1080 – 1180°C) is necessary. Rapid quenching is required.

Machining

The cold work hardening rate of Alloy 317L makes it less machinable than 410 stainless steel. The table below provides relevant machining data.

317 stainless steel plate application industry

317 stainless steel plate are mainly used in chemical, petrochemical, marine engineering, seawater pipelines, seawater desalination and other industries, nuclear engineering, paper and pulp industry.

oil and gas

Kuaima Steel provides a complete set of equipment and installations for drilling, transportation and storage in the oil and gas industry.

energy

Kuaima Steel serves the entire service cycle of power generation and synchronous activities in design, construction, repair and maintenance.

construction

Kuaima Steel provides comprehensive products and services for infrastructure, bridges, pipelines, etc.

marine

Kuaima Steel is a trusted supplier for subsea to surface operations and shipbuilding operations.

We supply and export 317 stainless steel plate in following countries

Malaysia, United Arab Emirates, Indonesia, Saudi Arabia, Iran, Qatar, India, China, United Kingdom, Singapore, Canada, Thailand, Korea, Turkey, Philippines, Egypt, Germany, Italy, Japan, Russia, Vietnam, Australia, South Africa , Portugal, Morocco, Costa Rica, Kazakhstan, Netherlands, Mexico, Brazil, France, Spain, Nigeria, Bangladesh, Kuwait, Iraq, Ukraine, Poland, Jordan, Romania, Oman, Hong Kong, Venezuela, Colombia, Norway, Chile, Te Trinidad and Tobago, Greece, Czech Republic, Belgium, Sri Lanka, Cyprus, Angola, Myanmar (Burma), United Kingdom, Canada, Korea, Thailand, Netherlands, Spain, Turkey, Australia, Mexico, Pakistan, Vietnam, Brazil, Philippines, France, Taiwan, Poland, South Africa, Russia, Nigeria, Kuwait, Czech Republic, Norway, Romania, Egypt, Oman, Sweden, Belgium, Hong Kong, Israel, Colombia, Switzerland, Denmark, Finland, Argentina, Venezuela, Peru, Ukraine , Chile, Bangladesh, Portugal, Ireland, Austria, Algeria, Greece, Iraq, New Zealand, Slovakia, Hungary, Kazakhstan, Slovenia, Lithuania, Serbia, Sri Lanka, Bahrain, Bulgaria, Morocco, Tunisia, Croatia, Jordan, Ecuador, Te Trinidad and Tobago, Estonia, Azerbaijan, Ghana, Lebanon, Cyprus, Dominican Republic, Latvia, Libya, Costa Rica, Cambodia, Macedonia (FYROM), Belarus, Jamaica, Palestine, Turkmenistan Belarus, Jamaica, Palestine, Turkmenistan Belarus, Jamaica, Palestine, Turkmenistan and other countries.

Steel Plate

Steel Plate steel pipe

steel pipe Stainless steel

Stainless steel

English

English Spanish

Spanish Russian

Russian Portuguese

Portuguese Section steel

Section steel carbon steel plate

carbon steel plate Steel plate processing

Steel plate processing steel coil

steel coil steel rod

steel rod

Home

Home