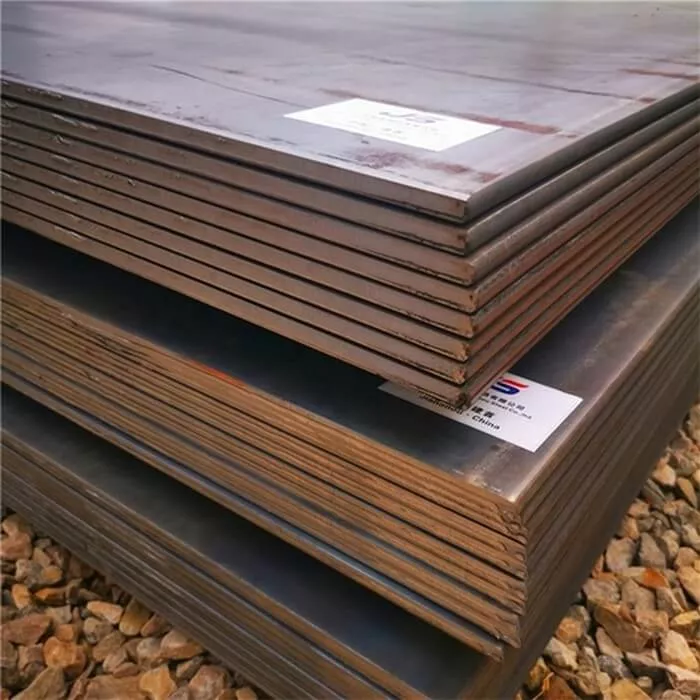

Product information of Q450NQR1 weathering and corrosion resistant steel plate

Q450NQR1 weathering steel refers to low alloy structural steel with protective rust layer and atmospheric corrosion resistance, which can be used to manufacture steel structures such as vehicles, bridges, towers, containers, etc. Compared with ordinary carbon steel, weathering steel has better corrosion resistance in the atmosphere. Compared with stainless steel, weathering steel has only a small amount of alloy elements, such as phosphorus, copper, chromium, nickel, molybdenum, niobium, vanadium, titanium, etc. The total amount of alloy elements only accounts for a few percent, unlike stainless steel, which accounts for more than ten percent, so the price is relatively low.

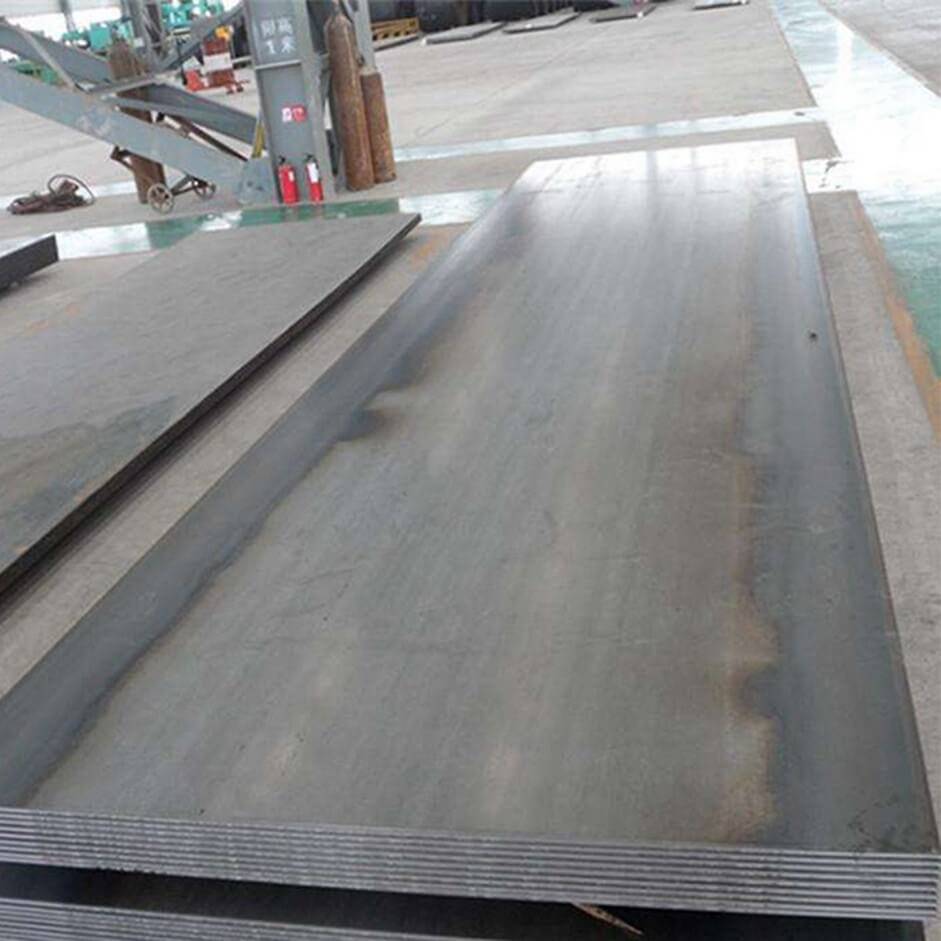

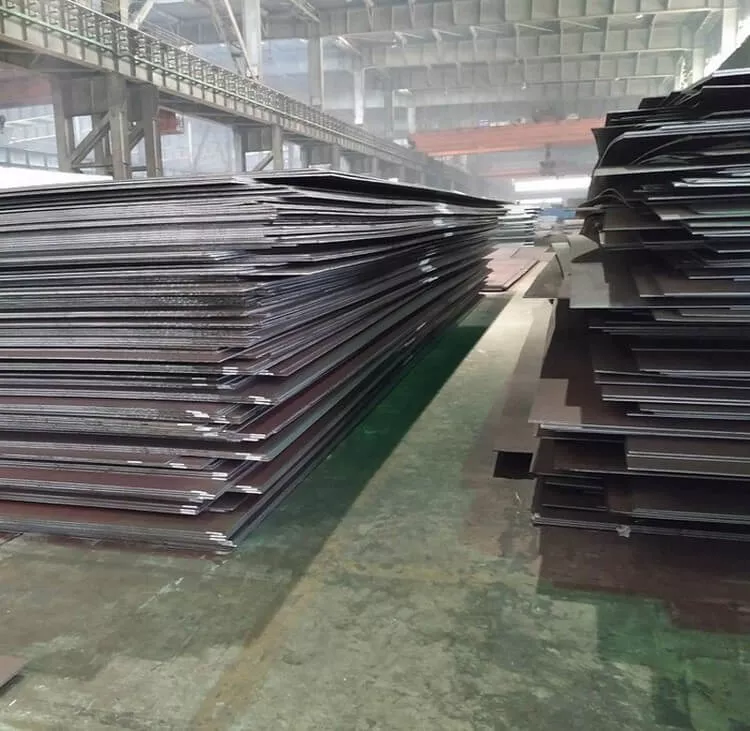

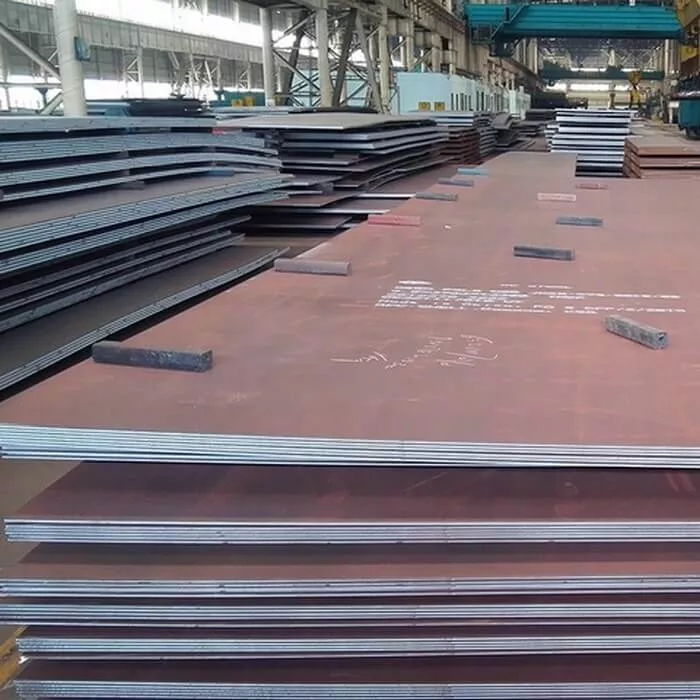

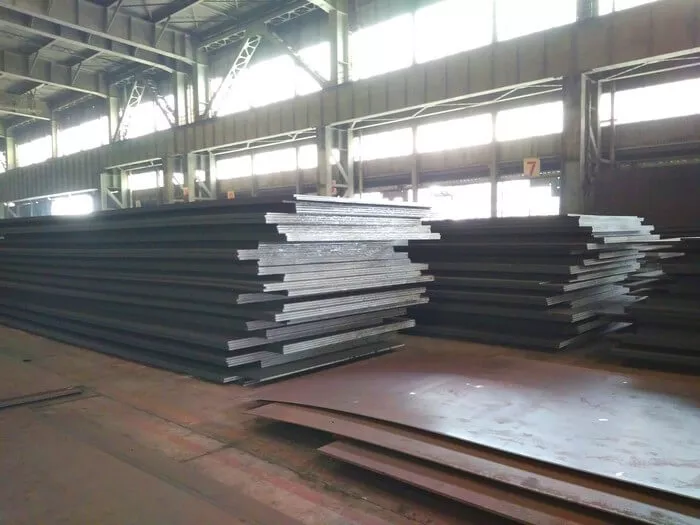

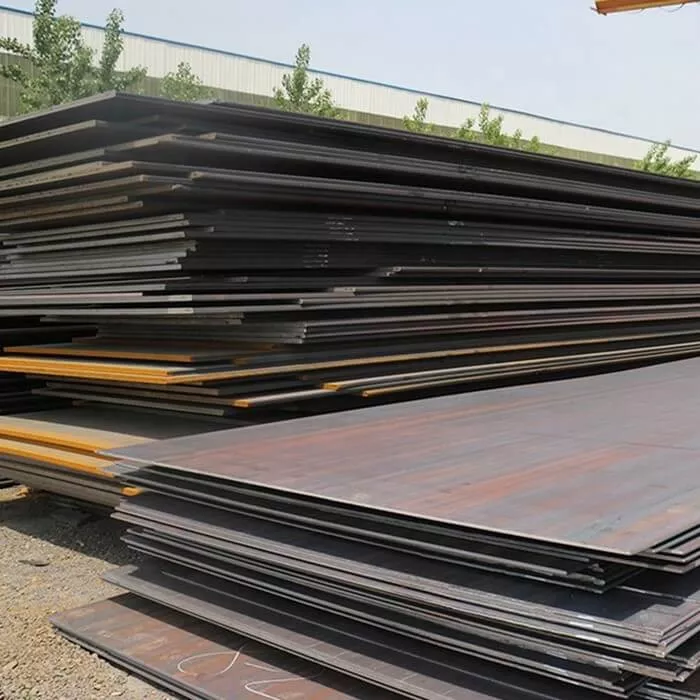

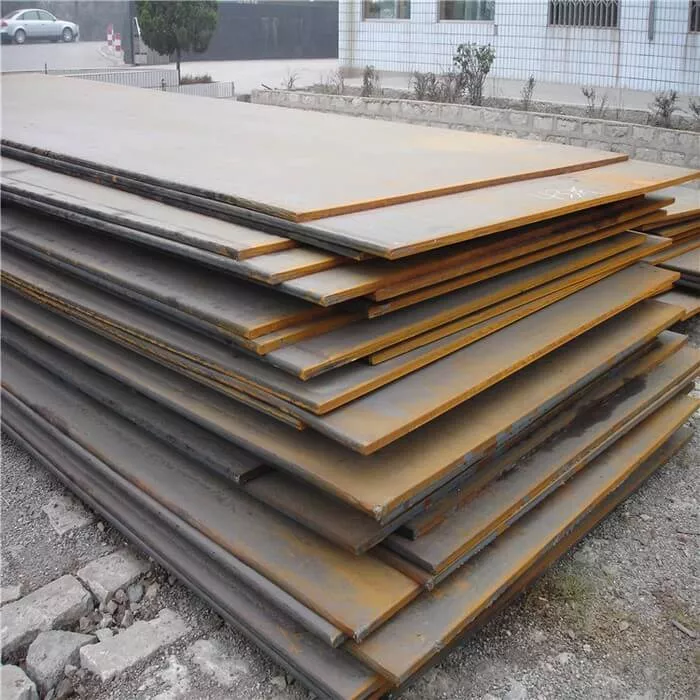

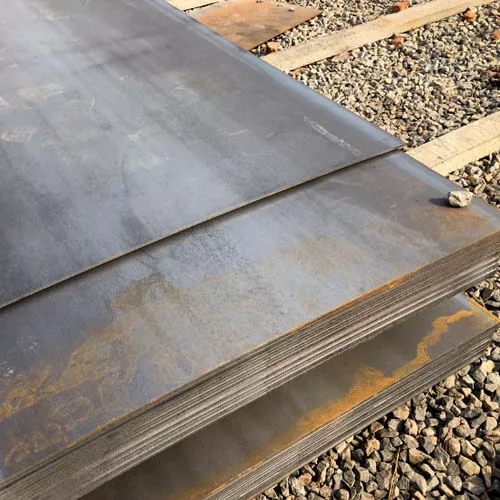

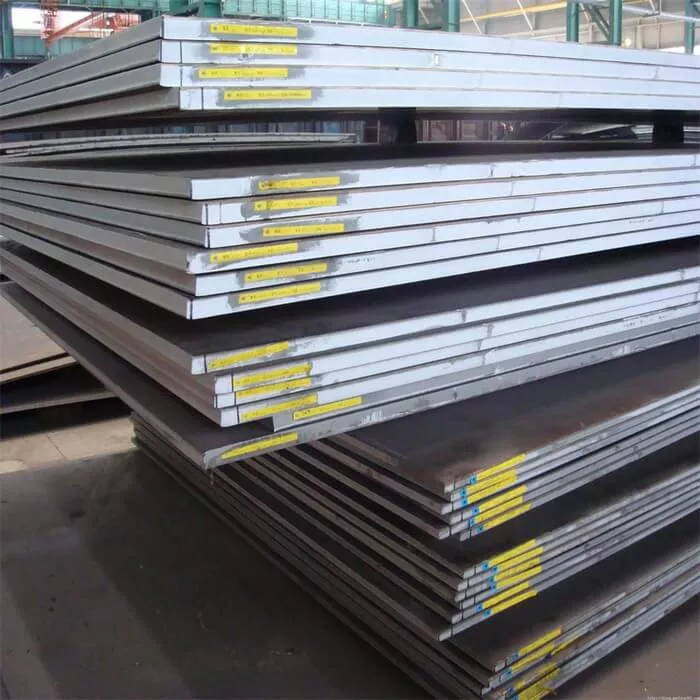

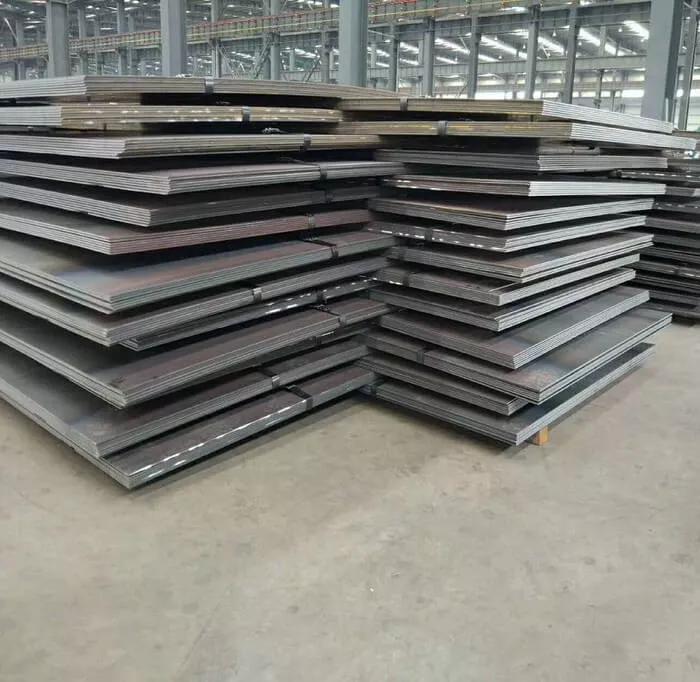

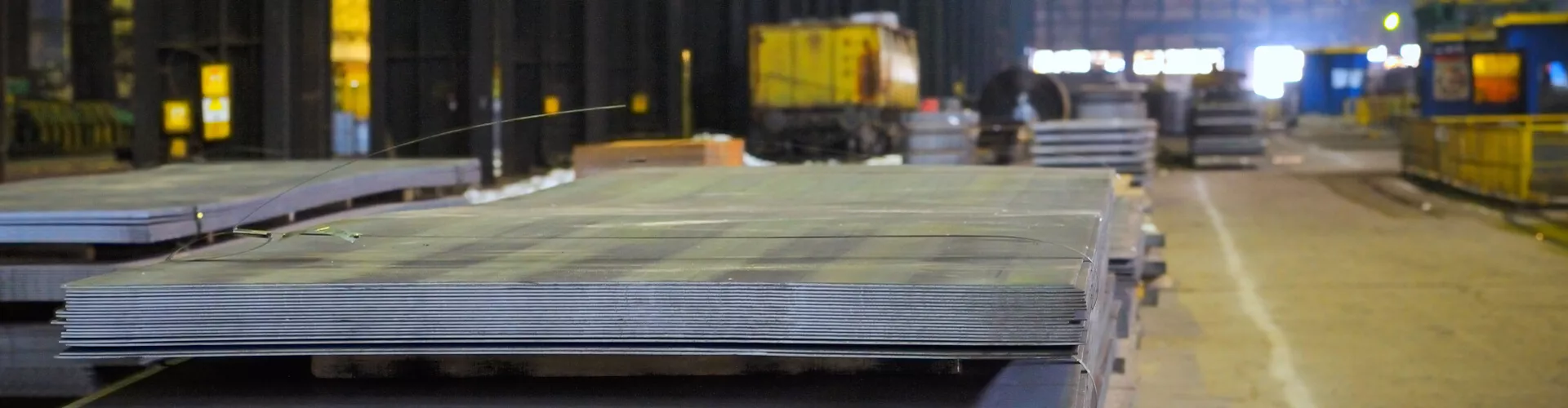

Weathering steel plate Production line

KUAIMA steel company has more than ten years of experience in diversified operations and multi-product transactions, involving round bar, ship plate, seamless pipe, plate, coil, wire, bright bar, pipe fittings and a wide range of carbon steel, alloy steel And more product sizes of stainless steel materials, these products we produce meet national and international quality standards, such as ASTM, ASME, DIN, JIS, ISO, etc. The company has 25 production lines for various products, with an annual output of 500,000 tons, and is committed to Provide high-quality steel products and provide supporting services and solutions for global customers. Welcome to KUAIMA steel company.

Weathering Steel Application industry

Weathering Steel are mainly used in chemical, petrochemical, marine engineering, seawater pipelines, seawater desalination and other industries, nuclear engineering, paper and pulp industry

oil and gas

Kuaima Steel provides a complete set of equipment and installations for drilling, transportation and storage in the oil and gas industry.

energy

Kuaima Steel serves the entire service cycle of power generation and synchronous activities in design, construction, repair and maintenance.

construction

Kuaima Steel provides comprehensive products and services for infrastructure, bridges, pipelines, etc.

marine

Kuaima Steel is a trusted supplier for subsea to surface operations and shipbuilding operations.

Weathering steel plate Application industry

Weathering steel plates are mainly used in chemical, petrochemical, marine engineering, seawater pipelines, seawater desalination and other industries, nuclear engineering, paper and pulp industry

oil and gas

Kuaima Steel provides a complete set of equipment and installations for drilling, transportation and storage in the oil and gas industry.

energy

Kuaima Steel serves the entire service cycle of power generation and synchronous activities in design, construction, repair and maintenance.

construction

Kuaima Steel provides comprehensive products and services for infrastructure, bridges, pipelines, etc.

marine

Kuaima Steel is a trusted supplier for subsea to surface operations and shipbuilding operations.

We supply and export Weathering steel plate in following countries

Malaysia, United Arab Emirates, Indonesia, Saudi Arabia, Iran, Qatar, India, China, United Kingdom, Singapore, Canada, Thailand, Korea, Turkey, Philippines, Egypt, Germany, Italy, Japan, Russia, Vietnam, Australia, South Africa , Portugal, Morocco, Costa Rica, Kazakhstan, Netherlands, Mexico, Brazil, France, Spain, Nigeria, Bangladesh, Kuwait, Iraq, Ukraine, Poland, Jordan, Romania, Oman, Hong Kong, Venezuela, Colombia, Norway, Chile, Te Trinidad and Tobago, Greece, Czech Republic, Belgium, Sri Lanka, Cyprus, Angola, Myanmar (Burma), United Kingdom, Canada, Korea, Thailand, Netherlands, Spain, Turkey, Australia, Mexico, Pakistan, Vietnam, Brazil, Philippines, France, Taiwan, Poland, South Africa, Russia, Nigeria, Kuwait, Czech Republic, Norway, Romania, Egypt, Oman, Sweden, Belgium, Hong Kong, Israel, Colombia, Switzerland, Denmark, Finland, Argentina, Venezuela, Peru, Ukraine , Chile, Bangladesh, Portugal, Ireland, Austria, Algeria, Greece, Iraq, New Zealand, Slovakia, Hungary, Kazakhstan, Slovenia, Lithuania, Serbia, Sri Lanka, Bahrain, Bulgaria, Morocco, Tunisia, Croatia, Jordan, Ecuador, Te Trinidad and Tobago, Estonia, Azerbaijan, Ghana, Lebanon, Cyprus, Dominican Republic, Latvia, Libya, Costa Rica, Cambodia, Macedonia (FYROM), Belarus, Jamaica, Palestine, Turkmenistan Belarus, Jamaica, Palestine, Turkmenistan Belarus, Jamaica, Palestine, Turkmenistan and other countries

Steel Plate

Steel Plate steel pipe

steel pipe Stainless steel

Stainless steel

English

English Spanish

Spanish Russian

Russian Portuguese

Portuguese Section steel

Section steel carbon steel plate

carbon steel plate Steel plate processing

Steel plate processing steel coil

steel coil steel rod

steel rod

Home

Home